Shipping containers are made from Corten steel, which allows them to deal with harsh elements in marine and other environments. They’re also designed and painted to withstand corrosion and wear and tear. While shipping containers are durable and require little maintenance, you still need to take care of them. Doing so will prolong their service life.

An annual or semi-regular maintenance is necessary to keep your cargo storage containers in good condition. That way, you can ensure that containers meet international safety guidelines when being transported over land, air, or water. Repairs don’t take too long as long as you catch any problems early on. Also, you need to know what to look for and where to look when doing the maintenance.

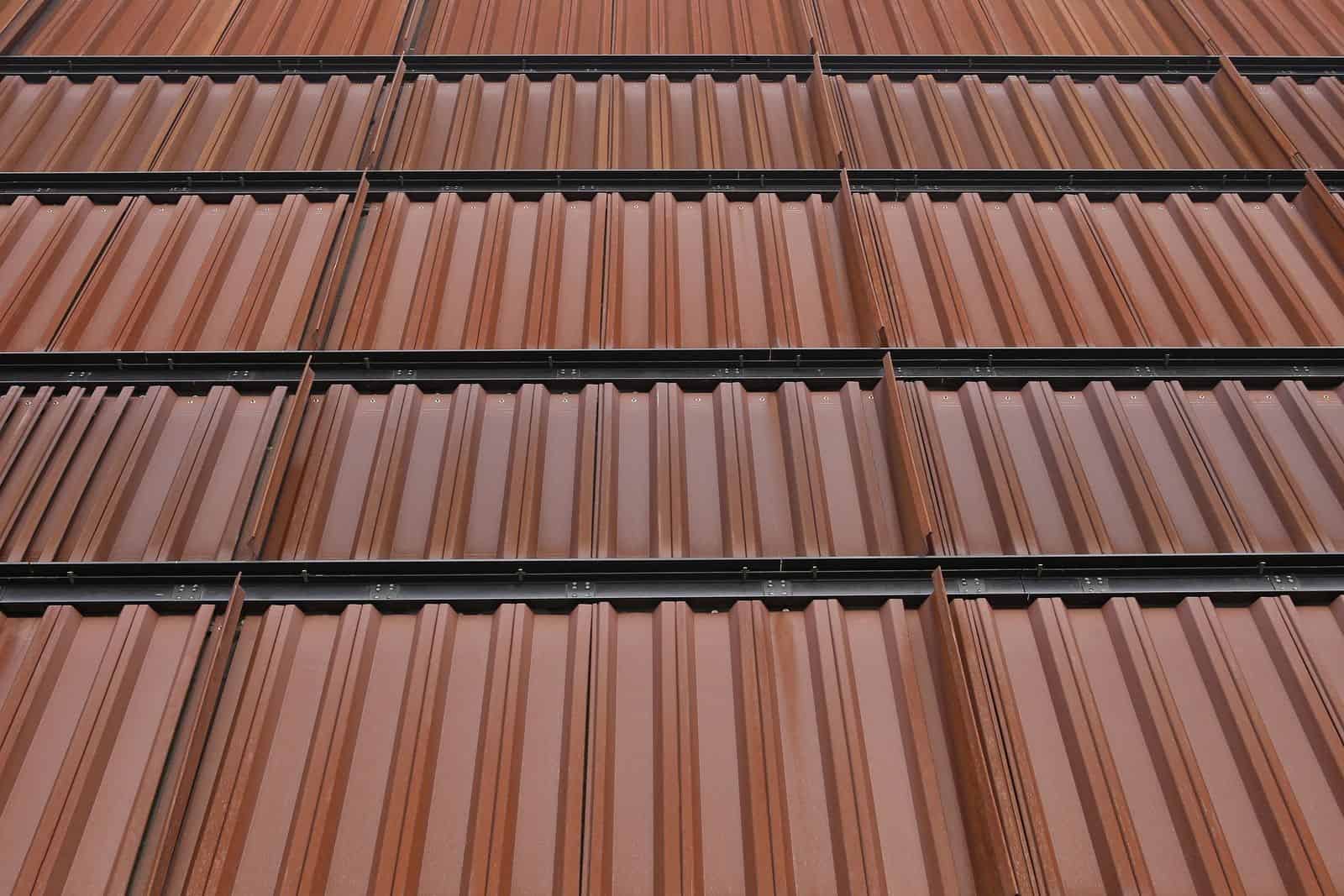

Check the Roof

The roof is one of the most important parts of a shipping container. You need to check the roof regularly and look for dents, which can occur when containers are stacked on top of each other. These dents can then collect rain water that causes corrosion. Get dents repaired immediately and the affected areas coated with appropriate paint.

Treat Rusted Areas

Steel is prone to rust caused by salt air environments. Just because your container is rust-resistant doesn’t mean you can be too complacent about its condition. In order to prevent rust, you need a specialist paint that can fight rust and prevent corrosion. Affected spots should be sealed, painted, and rust-proofed to keep your containers in good condition.

Lubricate Doors

The moving parts on the doors of shipping containers might be exposed to risk of damages and wear out due to frequent use. It has to be maintained to ensure that it’s always working properly. To look after the hinges and locking mechanisms of cargo storage containers, you have to clean and lubricate them.

A commercial grade cleaner can help get rid of dirt, rust, and grit that cling to door hinges and locking bars. A lubricating spray, on the other hand, can keep the hinges and bars functioning.

Inspect Container Modifications

When left in their original design, shipping containers can resist water and dirt traps, as well as corrosion. However, if they have been modified, you need to take a closer look at them. Cutting, joining, or stacking shipping containers makes maintenance a little bit more challenging since dirt, dust, and rust can get into joins and metal areas.

As part of maintenance, inspect the modifications done to the shipping containers. Make sure that the joins and metal on metal areas are clean. Spot any depressions and see if they’re collecting dirt and debris that could do damage in the long term.

Place it On a Proper Surface

Shipping containers must be set on an even surface. Otherwise, they could eventually fall out of square which makes them easy to tip over, as well as creating problems for storage. Also, an uneven surface could cause water collection in one area of the container, resulting in underside corrosion. The surface should be well drained as well.

Get Refrigeration Unit Servicing

In case you have a refrigerated container, professional maintenance is required. This is to spot problems before they get worse, allowing you to avoid downtime and expensive repairs. Because a refrigerated container involves mechanical and electrical systems, only technicians who have the right tools and training for it should make any necessary repairs.

Shipping containers have several advantages that make them fit for cargo storage use. However, they can only serve their purpose to the fullest if they are kept in good working condition. Sourcing from reliable suppliers assures you of high quality shipping containers. They may even give you valuable maintenance tips to keep your containers in top shape for longer.

Sources:

Long Term Storage: Shipping and Storage Containers, Containerauction.com

How to Take Care of Cargo on Container Ships at Sea? Marineinsight.com